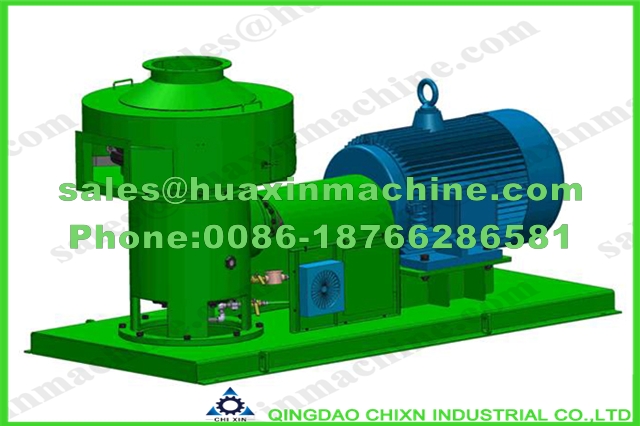

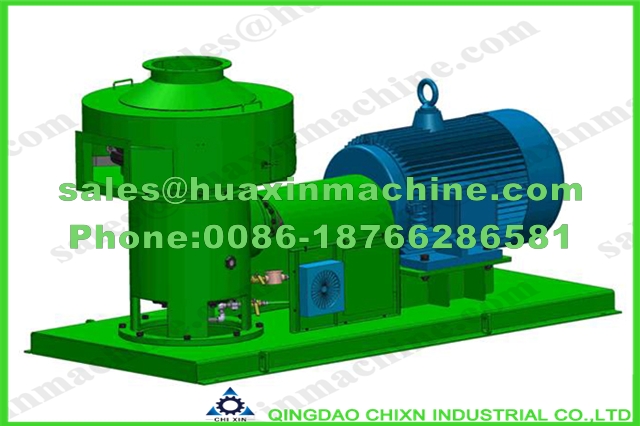

HM series vertical ring die pellet mill

Products:

HM series vertical ring die pellet mill, is learn from the pellet mill structure and years of market feedback, well-developed new products. Precision gear drive, compact structure.

This product is suitable for: organic fertilizer, bio-organic fertilizer and organic-inorganic compound fertilizer granulation; granulated sawdust, straw and other biomass fuel particles; the feed, forage granulated particles. Apply a wide range, good particle mass. Applies fertilizer plants, feed mills, wood processing plants, fuel plants, chemical plants, etc., is the ideal compact compression molding equipment.

Features:

1, the ring mold stand set, which will help feed and difficult knot arch.

2, the material was centrifuged at molding cavity distribution, particle shape good quality.

3, the ring mold, die hole aspect ratio range, wide adaptation of materials.

4, the optimum design ring mold / pressure roller system to facilitate the clearance adjustment, improve extrusion efficiency and enhance durability.

5, precision gears, torque, high efficiency, low noise and good stability.

6, since the circulation lubrication and cooling systems, to improve the stability of the equipment, reduce power consumption tons of material.

7, cut material scraper simplify design, save parts replacement costs.

Specification

Model |

HM700

|

|

Main motor power (kW)

|

75

|

|

capacity(t/h)

|

1.5—4

|

|

ring dia inner diameter (mm)

|

672

|

|

die size(mm)

|

Ø2—Ø14

|

|

weight (kg)

|

2400

|

|

dimension(L*W*H))

|

2750*1300*1500

|